Protein purification tailored to your needs

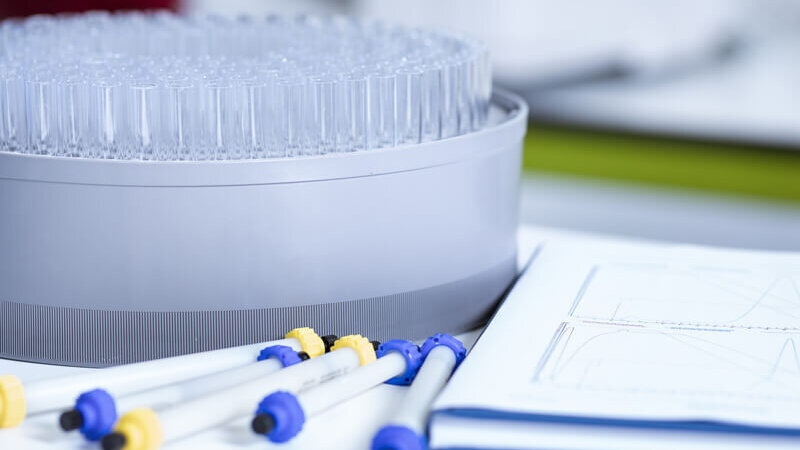

VALIDOGEN’s protein purification development service complements strain development and protein production fermentation with a fully integrated downstream process development approach.

Our downstream processing (DSP) experts design, optimize, and scale purification workflows to ensure high yield, purity, and process robustness across all application areas - from biopharmaceuticals to industrial enzymes.

In close collaboration with our customers, we optimize chromatography steps, determine binding capacities, and fine-tune process parameters to achieve the desired product quality while maintaining cost-efficiency and scalability. We also design and refine non-chromatographic purification methods, including microfiltration, ultrafiltration, and diafiltration, to complement chromatographic steps or, where appropriate, to serve as stand-alone, economically efficient purification solutions.

This integrated approach, spanning cultivation, purification, and analytics, enables efficient, high-quality recombinant protein production suitable for diverse industries and regulatory frameworks.